Mining for Souls

Page 44

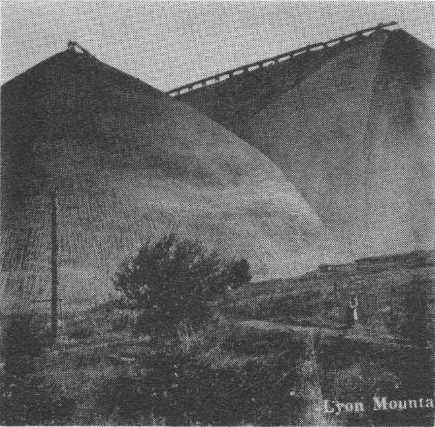

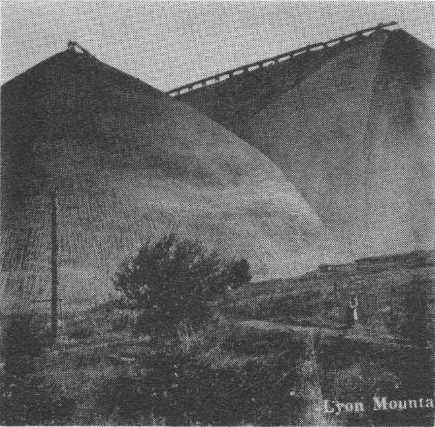

Operations of the Chateaugay Division of Republic

Steel, at Lyon Mountain

by William J. Linney

Page 2

Operations of the Chateaugay Division of Republic

Steel, at Lyon Mountain

by William J. Linney

Page 2

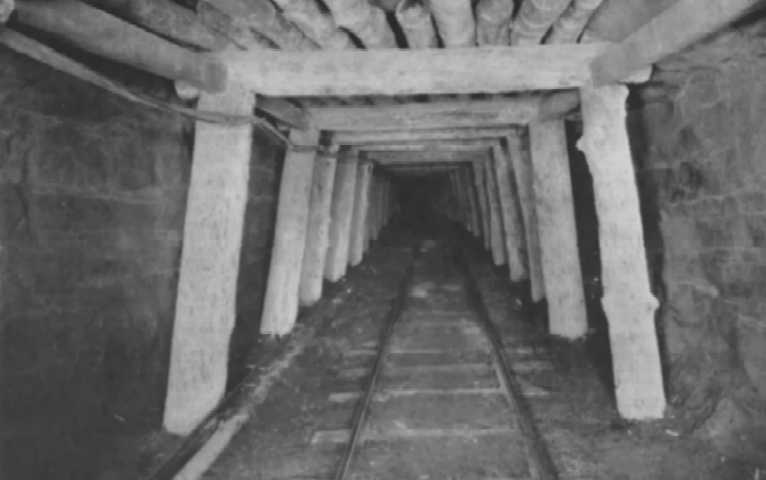

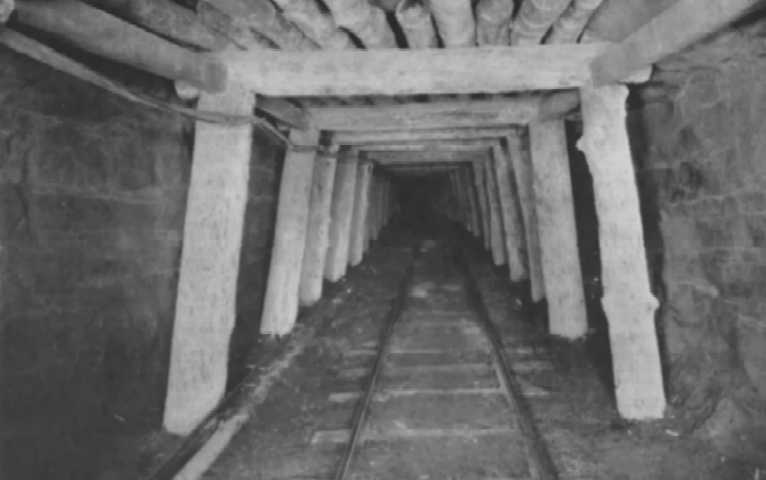

Main haulage drift - 1813 ft. level

Milling and Concentrating

Main haulage drift - 1813 ft. level

Milling and Concentrating

Chateaugay ore, as mined, contains 25 per

cent iron. By milling and magnetic concentration the iron content is brought

up to 68 per cent. Pure magnetite contains 72.4 per cent iron and 27.6 per

cent oxygen

When the ore comes from the mine it is 8 in. and

smaller in size. The fines, 1/2 in. and smaller, are screened out and conveyed

by an 18-in. belt conveyor to the fine silo. The coarse, 4 in. and larger,

is crushed to 3 in. by two 10 by 72-in. jaw crushers in the head house at

the top of the main hoisting shaft. Ore from the crushers, along with the

minus 1/2 in. which bypasses the crushers, is conveyed by a 30-in. belt

conveyor to a crushing plant, where it is passed over a double-deck screen.

That passing a 1/2-in. screen is conveyed to a fine silo; that passing a

2-in. screen and retained on a 1/2-in. screen is conveyed by a 30-in. belt

conveyor to a coarse silo; and that passing over a 2-in. screen discharges

into a 4-ft. cone crusher. The cone-crusher product is returned in closed

circuit to the double-deck screen at the top of the crushing plant.

Material from the coarse silo goes to two 36-in.

pulley-type electromagnetic separators which are set and regulated discard

all material containing less than 3 per cent iron. The iron-bearing material

retained by the separator is discharged to a 5«-ft. coile crusher set

to ~ in. which product is conveyed by a 30-in. belt conveyor to the sCI.oIl(tIly

crushing Iniuding.

Material from the mine silo is conveyed by an

18-in. belt conveyor to a lift-and-bucket-type elevator and discharged into

a dryer. This is a steel stack, 125 ft. high, lined with firetijick and

equipped with cast-iron baffles, heated by the hot gases from a chain

stoker, burning anthracite rice coal. 'Thoroughly dried. the material goes

on to a 24-in. steel conveyor and is discharged into the same 30-in. belt

conveyor that carried the product from the 5«,-lt. cone crusher.

The next step is to pass it over two 5 by

12-ft. doulde-deck vibrating screen , having 1/2-in. openings

on tile toll deck and 10-mesh openings on the bottom deck. The portion that

passes over the 1/2-in. screen is returned in closed circuit to the 51/2-ft.

cone crusher and the 10-mesh oversize goes to four 4 by 12-ft. vibrating

screens with 10-mesh openings. Oversize from the vibrating screens goes to

four 36-in.pulley-type magnetic separators which are set and regulated to

discard all material containing less than 3 percent magnetic iron. Magnetic

material retained by the separators is conveyed Ily 30-in. belt coliveyors

to a 9 by 16-It. (try rod mill, the product from which is returned in closed

circuit to the screens at the top of the building.

Ore passing the 10-mesh screens is sent to a 30-ft.

centrifugal air separator flIr taking out the minus-100-niesh material,

which is sent direct to wet magnetic separators. The coarse material from

the air separator, which is minus 10 mesh and plus 100 mesh, is conveyed

by a 30-in. belt conveyor direct to the bins over the dry magnetic separators

in the concentrating house.

Minus-lO-inesh dry material

now passes over sixteen 30-in. drum-type, electromagnetic separators, making

a concentrate containing 68 per cent iron or better, and a tailing containing

not more than 3 per cent magnetic iron. The middling from these separators

falls by gravity to sixteen separators of similar type directly below, which

also make a concentrate containing 611

per cent iron or better, and a taHing containing not more than 3 per cent

magnetic iron. Middling from these separators ii returned to the tins

at tll~ top of the building in closed circuit. Concentrate is sent to two

500-ton storage hins at the top of the sintering plant and the tailing goes

to the tailing p~e.

Because the minus-TOO-mesh material cannot be

efficiently separated on dry drum-type magnetic separators, it is sent to

wet inclined-belt magnetic separators which make a 70 per cent iron concentrate

and a tailing containing not more than 2 per cent magnetic iron. The concentrate

is sent to a filter and then to the storage bin above the sintering plant.

Ore tailing, or rock that has been separated from

the ore, has become a valuable by-product. Each commercial size is stored

separately in piles above a concrete tunnel, through which a 36-hi. belt

conveyor takes it to railroad cars for shipment to market. Hundreds of thousands

of tons of ore tailing was shipped in 1942.

The concentrating plant has a capacity for treating

efficiently 4500 long tons of crude ore in 24 hours, from which 1400 long

tons of concentrate containing 68 per cent iron is produced. Within

the next few inlIoths the concentrating mill will be changed

over entirely to the wet process, using wet inclined-belt magnetic separators.

Sintering the Concentrate

Sintering is accomplished by means of the

continuous process. The sinter machine is 6 ft. wide and 82 ft. long, comprised

of a series of grates known as pallets which are mounted on wheels for traveling

(In a continumis track

Concentrated ore is first mixed with about 51/2

per cent by weight of anthracite. The grade of fuel used is about

the size of granulated sugar, high in carbon and low in ash, and is known

as "anthrafine." As the fuel and concentrate are being mixed, by means of

a pug mill, a small amount of water is added as a temporary hinder. The mixture

of ore and fuel is spread evenly on the pallets of the sintering machine

to a thickness of about 71/2 in., and the fuel is immediately ignited as

it passes under an oil-heated ignition furnace comprised of refractory brick,

and a retort, or combustion chamber, suspended by a steel and cast-iron frame.

Combustion is assisted by a downward current of

air, drawn through the mixture or bed, the entire length of the machine,

by a large induced-draft fan with a capacity of 90.000 cu.ft. of air per minute.

The speed at which the machine travels is regulated so that, by the time

the material reaches the discharge end, the fuel is entirely burned out and

the process cmnpleted. The sinter is then discharged over a set of stationary

grizzly bars, spaced 1 iii. apart, which take out the lilies, allowing only

the coarse material to go to the railroad car for shipment. The lines are

returned, by means of an indined belt conveyor, and are lii~ \:ed

with the incoming feed to the sulterill machine.

The plant has an output capacity of 58 long tons

of sintered ore per hour, six days per week, and can be operated continuously

and efficiently 24 hours daily by suspending operations 8 hours each week.

Tailings Piles

Tailings Piles

Myers-Whaley shovel underground

Myers-Whaley shovel underground

Sources:

Adirondack Museum photos, Blue Mountain Lake, NY;

History of Clinton County, New York;

from History of Mining of Chateaugay

Ore and Iron Company.

Go to Page 1 of The History of Lyon

Mountain.

Go to Page 3 of The History of

Lyon Mountain.

Go to Mining History for The History

of Mining in the North Country.

Go to Page 5 of The History of Lyon

Mountain.(for article on Lyon Mt. and Mineville)

Go to Page 45 of Mining for Souls.

Back to Page 43 of Mining for Souls.

Go to Page 1 of Mining for Souls.(cover

page)

Rod Bigelow

Box 13 Chazy Lake

Rod Bigelow

Box 13 Chazy Lake

Dannemora, N.Y. 12929

rodbigelow@netzero.net

rodbigelow@netzero.net  BACK TO

THE HISTORY PAGE

BACK TO

THE HISTORY PAGE

BACK TO BIGELOW

HOME PAGE

BACK TO BIGELOW

HOME PAGE