Mining for Souls

Page 43

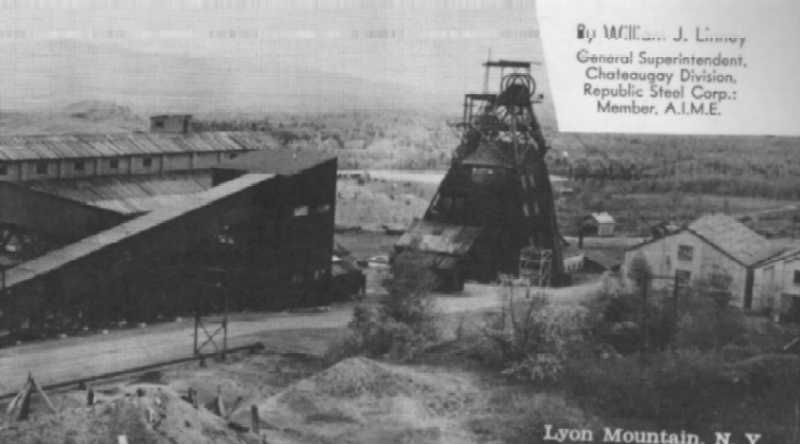

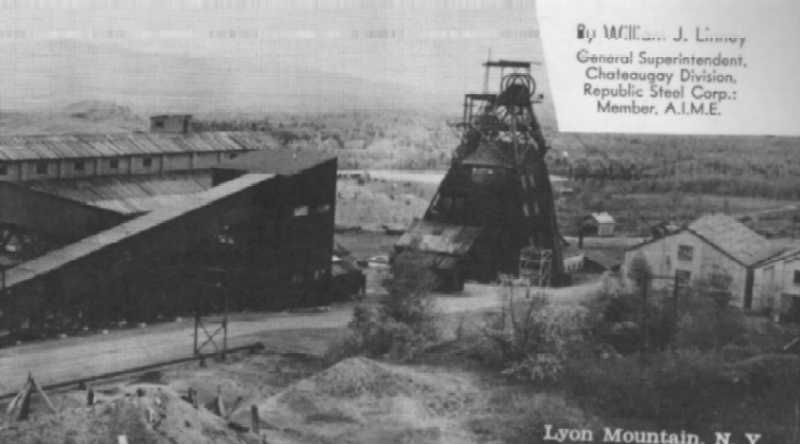

Operations of the Chateaugay Division of Republic

Steel, at Lyon Mountain

by William J. Linney

Operations of the Chateaugay Division of Republic

Steel, at Lyon Mountain

by William J. Linney

Headframe on main hoisting shaft.

Headframe on main hoisting shaft.

Magnetite ore from Lyon Mountain,

so - called "Low Phos Chateaugay," has long been known to the iron

and steel industry for its almost complete absence of impurities. These

magnetites occur along the northern foothills of the Adirondacks in

several parallel and folded stringers which are continuous for several miles,

striking generally northeast-southwest and dipping usually over 45~ to the

northwest, or roughly toward the St. Lawrence River. Ore of minable thickness

is found in shoots of various sizes as to length and breadth, but of undetermined

and possible great depth.

The present hoisting shaft at Lyon Mountain is

in ihe largest of the known shoots; one that is several thousand feet long

at the surface and that has an average minable thickness of about 15 ft. of

25 per cent iron. Mineralized zones often penetrate further into the hanging

or footwall, but these are not of economic trade. This ore shoot is folded

and twisted into intricate patterns and is also cut by pegmatites, asic

dikes, and faults.

These veins or stringers of magnejites probably

originated during the Adirondack mountain~forming period of the Pre-Cambrian,

when the Grenville series of sediments was intruded by the syenites, anorthosites,

granites, etc., to form the Adirondacks. Some of the Grenville rocks were

not assimilated by the intruding magma but were probably trapped and metamorphosed

in the mass of sycnite. Dynamic forces of heat and pressure then went

to work to form the "flow" structure, and chemical reactions took place

in which replacement and transfer of minerals occurred, helped along by

hot, gaseous solutions. Some of these reactions were apparently aided by

the type of minerals originally part of tile old Grenville sediment. The

result has been a concentration of magnetite and iron minerals in some of

the gray gneisses. Thus the old Grenville rocks are responsible to a large

extent for another of the many economic minerals already

credited to them in other parts of North America.

Closely related to the magmatic intrusions and

dynamic upheaval was the pegmatitic phase in which the more fluid acid rocks

in turn invaded the Grenville ore series, thereby "cutting off" some of the

ore. Intrusions of basic dikes and faulting were the latest of the forces

which shifted the ore veins to some extent.

Exploration of these deposits is difficult because

of the complicated folding, which often causes a drawing-out or dunning

of the ore in anticlines, and a thickening in synclines or troughs.

Further complications are encountered in (lip-needle work as it is almost

impossible to distinguish between a series of stringers and a minable ore

shoot by use of this instrument. Consequently extensive use of the diamond

core drill is found to be essential to both the exploration and development

of the ore bodies.

Mining Practice

Main entrance to the mine is through an 8 by 24-ft.,

63' incline shaft which is sunk, mostly in the footwall, to a depth of 2350

ft. The vein is tapped from the shaft at intervals varying from 150 to 300

ft.

Levels, or drifts, 8 by 12 ft., are driven east

and west of the shaft on the strike of the vein. The drifts are driven on

a rising grade of 3A of 1 per cent in order to facilitate drainage and favor

transportation, the loaded cars traveling on the downgrade. As the drifts

advance, a permanent 36-in. gauge track is laid with 60-lb. steel rail on

good sound wooden ties spaced 30 in. apart, ballasted with iron ore or rock,

whichever is met in driving the drift.

Wherever the vein is steep enough, which it is

in most places, raises 5 by 8 ft., spaced on 30-ft. centers, are driven up

into the ore above the drift, from which stopes are started for mining the

ore for production. Chutes, usually made of 3-in. hardwood plank and timber

with a 3/5-in. steel-plate liner, using an underhand arc gate and 10 by 30-in.

air lift, are installed in the bottom of the raises through which the ore,

after it has been broken, is loaded into the tram cars.

A variation of this method of installing chutes

is to drive a subdrift approximately 40 ft. above the main drift. From this

subdrift, i'aises are driven on 30-ft. centers. The ore comes down into

the subdrift and is scraped by 50-hp. electric hoists to a main ore pocket.

The advantage of this subdrift is that only one chute need be built. It

is less hazardous when drawing ore from the stopes. At each end of a stope,

a manway raise, 6 by 8 ft., is driven through to the level above for ventilation,

pipe, and ladderways, and to afford entrance to the stope.

Three kinds of stoping methods are used in fliing

the ore. shrinkage, underhand, and scraper.

The shrinkage method is the one, consisting of

drilling up into the ore, blasting it down, and drawing only enough ore out

of the stope each day to leave space for the men to work, completing a daily

cycle. This is continued until the stope is advanced to

within 30 ft. of the l~vel above, during which time about 40 per cent of

the ore broken is drawn out daily. and 60 percent left in. Thus. when the

stope is completed. it is full of broken ore which can he drawn out at will.

The underhand method consists of drilling down

into the ore and blasting it from sublevels which have been driven across

the stope at 50-ft. intervals, connecting both manway raises. As the ore is

broken, it falls by gravity to the loading chutes below, and can ah be drawn

out immediately.

In places where the vein is not steep enough for

the ore to run by gravity the scraper method can be used. At convenient

locations, a small, doubledrum, electrically-driven hoist is installed,

equipped with 5/5-in. steel cables, to which is attached a steel

scraper. After the ore has been drilled and blasted it is scraped along

the floor to small ore pockets, from which it is loaded by gravity into

the tram cars.

Transportation of the ore from the working places

to the main hoisting shaft is accomplished by storage-battery locomotives

hauling steel, side-dump cars of the Granhy type, each having a capacity

of 6 long tons. and equipped with roller bearings. Loading and tramming of

each train is done by two men, averaging 55 long tons per man per day for

the entire mine.

After the ore is trammed to the main hoisting shaft.

it is dumped into the ore pass which is connected to each level. At the bottom

of this ore pass is a large 48 by 36-in. jaw crusher reducing lumps to 8

in. or smaller. The crushed ore is discharged by gravity into the skip loading

bins, loaded into the 8-ton skips, hoisted at the rate of 1800 ft. per mm.,

and dumped automatically into the bins above the secondary crushers in the

headframe at the top of the shaft.

Splendid ventilation is provided in an unusual

and inexpensive way. Openings from the old workings to the surface at the

extreme westerly end of the mine are considerably higher than those on the

easterly end. During the long, cold winter months, tremendous quantities of

ice, hundreds of thousands of tons, accumulate in these workings, which cools

the air sufficiently to cause large volumes to go down into the workings,

forcing the smoke and gases out through the openings to the surface on the

easterly end of the mine. The ice, of course, melts considerably during

the summer months but never entirely, enough fortunately remaining to ensure

ample ventilation of the mine at all times.

The entire mine is arranged so that the water

from all sections drains by gravity to points at, or near, the main hoisting

shaft, from which it is pumped to the surface by electrically-driven pumps.

The quantity is about 700 g.p.m. It is quite pure and contains no acids so

is not destructive to the pumping equipment.

In many places in the mine. especially on the

lower levels, much timbering must be done to support the back, or roof,

of the main drifts, on account of the tendency of the ore and rock to spall

and loosen.

The mine, as now developed and equipped, is capable

of producing 4500 long tons of ore, by drilling eight hours per day, tramming

ore sixteen hours per day, and hoisting twenty hours per day.

Milling and Concentrating

CHATEAUGAY ore, as mined, contains 25 per

cent iron. By milling and magnetic concentration the iron content is brought

up to 68 percent. Pure magoetite contains 72.4 percent iron and 27.6 per

cent oxygen. When the ore comes from the mine it is 8 in. and smaller in

size. The fines, 1/2 in. and smaller, are screened out and conveyed by an

18-in. belt conveyor to the fine silo. The coarse, 4 in. and larger, is crushed

to 3 in. by two 10 by 72-in. jaw crushers in the head house at the top of

the main hoisting shaft. Ore from the crushers, long with the minus 1/2 in.

which by-passes the crushers, is conveyed by a 30-in. belt conveyor to a

crushing plant, where it is passed over a double-deck screen. That passing

a 3-in. screen is conveyed to a fine silo; that passing a 2-in. screen and

retained on a 1/2-in.

continued on Page 4 of Mining History

Sources:

Adirondack Museum photos, Blue Mountain Lake, NY;

History of Clinton County, New York;

from History of Mining of Chateaugay

Ore and Iron Company.

Go to Page 1 of The History of Lyon

Mountain.

Go to Page 3 of The History of

Lyon Mountain.

Go to Mining History for The History

of Mining in the North Country.

Go to Page 5 of The History of Lyon

Mountain.(for article on Lyon Mt. and Mineville)

Go to Page 44 of Mining for Souls.

Back to Page 42 of Mining for Souls.

Go to Page 1 of Mining for Souls.(cover

page)

Rod Bigelow

Box 13 Chazy Lake

Rod Bigelow

Box 13 Chazy Lake

Dannemora, N.Y. 12929

rodbigelow@netzero.net

rodbigelow@netzero.net  BACK TO

THE HISTORY PAGE

BACK TO

THE HISTORY PAGE

BACK TO BIGELOW

HOME PAGE

BACK TO BIGELOW

HOME PAGE