Mining for Souls

Page 41

DEVELOPMENT OF LYON MOUNTAIN, N Y. AS A MINING ENTERPRISE

DEVELOPMENT OF LYON MOUNTAIN, N Y. AS A MINING ENTERPRISE

Early 19th century ore separator in Adirondacks.

[adk19th.jpg = larger picture]

Picture from History of Mining

of Chateaugay Ore and Iron Company

Early 19th century ore separator in Adirondacks.

[adk19th.jpg = larger picture]

Picture from History of Mining

of Chateaugay Ore and Iron Company

In 1803 William Bailey erected a Catalan forge

on the Chateaugay River about five miles below the outlet of Chateaugay

Lake He obtained his ore from what later became known as the Prall vein

of the 81 mine of the Chateaugay ore bed. The land area comprising the abandoned

Prall vein and what was to become the Chateaugay ore bed was purchased by

Lloyd N. Rogers in 1832. The actual discovery of the Chateaugay ore body

is credited to a trapper named Collins in 1823.

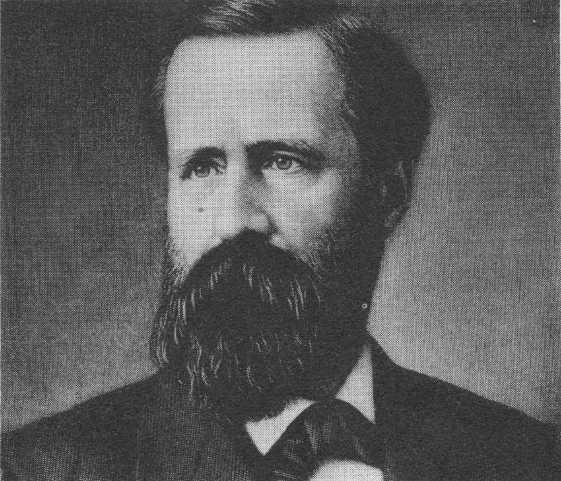

Smith M. Weed - One of founders of Chateaugay Ore and Iron Co.

Smith M. Weed - One of founders of Chateaugay Ore and Iron Co.

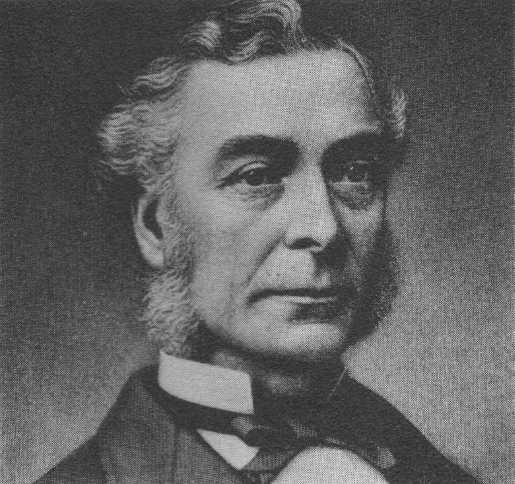

Andrew Williams - One of founders of Chateaugay Ore and Iron Co.

Andrew Williams and Smith M. Weed were the founders

of the Chateaugay Ore and Iron Company. They obtained control of the property

from Lloyd Rogers' son in 1868 and mined ore in summer months to be moved

during winter by horse drawn sleighs through the dense wilderness to Catalan

forges on the Saranac River. Transportation was a serious problem

for many years but the output from the ore bed grew and by 1874 twenty Catalan

forges together with charcoal kilns were erected at the outlet of Chateaugay

Lake. All the wood, coal and ore were moved on the lake in barges hauled

by steamboat in summer and by horses and sleds over the snow in winter.

The blooms and billets of iron produced from the forge operations were hauled

by wagons and sleighs to Chateaugay and shipped via the Ogdensburg and Lake

Champlain Railroad to Pennsylvania and Ohio steel mills.

Andrew Williams - One of founders of Chateaugay Ore and Iron Co.

Andrew Williams and Smith M. Weed were the founders

of the Chateaugay Ore and Iron Company. They obtained control of the property

from Lloyd Rogers' son in 1868 and mined ore in summer months to be moved

during winter by horse drawn sleighs through the dense wilderness to Catalan

forges on the Saranac River. Transportation was a serious problem

for many years but the output from the ore bed grew and by 1874 twenty Catalan

forges together with charcoal kilns were erected at the outlet of Chateaugay

Lake. All the wood, coal and ore were moved on the lake in barges hauled

by steamboat in summer and by horses and sleds over the snow in winter.

The blooms and billets of iron produced from the forge operations were hauled

by wagons and sleighs to Chateaugay and shipped via the Ogdensburg and Lake

Champlain Railroad to Pennsylvania and Ohio steel mills.

In the years immediately preceding the first

World War a well-defined study of the property was made, including a magnetometric

and geological survey, diamond drilling, chemical analysis, and surveying

and mapping the mine workings. The results revealed that the Chateaugay

ore beds were tremendous in size, containing an almost endless supply of

iron ore practically free from sulphur and phosphorus. So, in 1914,

plans were made for the development of the ore body on a large scale, which

included a new hoisting shaft, 1600 feet deep, with steel headframe and modern

electrically-driven hoisting equipment. War demands on production forced

postponement of development work until 1919. The No. 1 shaft which

had been sunk to a depth of 900 ft., was then extended to a depth of 1685

ft., with four compartments; one for pipe and ladderways, one for men and

supplies and two for hoisting ore, all enclosed in steel and concrete. Levels

and stopes were opened up, electric locomotives installed, and by 1924 all

mining operations were confined to the new No. 1 shaft.

continued on Page 2 of Mining History

Sources:

Adirondack Museum photos, Blue Mountain Lake, NY;

History of Clinton County, New York;

from History of Mining of Chateaugay

Ore and Iron Company.

Go to Page 1 of The History of Lyon

Mountain.

Go to Page 3 of The History of

Lyon Mountain.

Go to Mining History for The

History of Mining in the North Country.

Go to Page 5 of The History of Lyon

Mountain.(for article on Lyon Mt. and Mineville)

Go to Page 42 of Mining for Souls.

Back to Page 40 of Mining for

Souls.

Go to Page 1 of Mining for Souls.(cover

page)

Rod Bigelow

Box 13 Chazy Lake

Rod Bigelow

Box 13 Chazy Lake

Dannemora, N.Y. 12929

rodbigelow@netzero.net

rodbigelow@netzero.net  BACK TO

THE HISTORY PAGE

BACK TO

THE HISTORY PAGE

BACK TO

BIGELOW HOME PAGE

BACK TO

BIGELOW HOME PAGE