Mining and Manufacturing Chateaugay Products

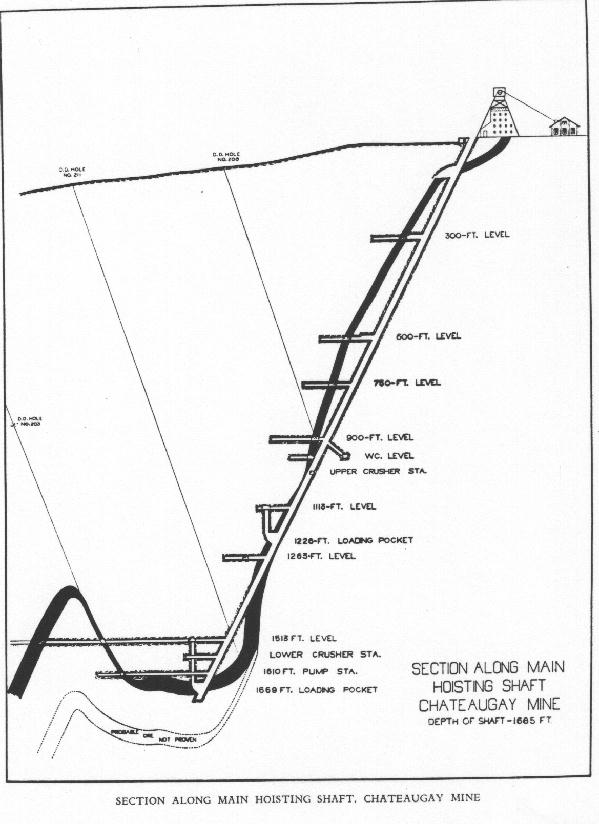

The main entrance to the mine is through an 8 ft. x 24 ft., 63 degree

incline shaft, sunk,

mostly in the footwall, to a depth of 1,685 feet, the vein

being tapped from the

shaft at suitable intervals, varying from 150 to 300 feet.

Levels, or drifts, 8 ft. x 12 ft., are driven east and west of the shaft,

on

the strike of the vein.

The drifts are driven on a rising grade of 3/4 of 1 per

cent in order to facilitate

drainage and favor transportation, the loaded cars

traveling on the down-grade.

As the drifts advance, a permanent 36" gauge

track is laid, with

40 lb. steel rail, on good, sound, wooden ties, spaced 30"

apart, ballasted with

iron ore, or rock, whichever the drift might be driven

through.

Wherever the vein is steep enough, which it is in most places, raises

5 ft. x 8 ft., spaced

on 30 foot centers, are driven up into the ore above the

drift, from which stopes

are started, for mining the ore for production. Chutes,

usually made of 3 inch

hardwood plank and timber, are installed in the bottom

of the raises, through

which the ore, after it has been broken, is loaded into the

tram cars. At

each end of a stope, a manway raise, 6 ft. x 8 ft., is driven

through to the level

above for ventilation, pipe and ladderways, and to afford

entrance to the stopes.

There are three kinds of stoping methods used in winning the ore:

shrinkage, underhand

and scraper.

The shrinkage method consists of drilling up into the ore, blasting it

down, and drawing only

enough ore out of the stope each day to leave space for

the men to work, completing

a daily cycle, which is continued until the stope is

advanced to within

30 feet of the level above, during which time about 40 per

cent of the ore broken

is drawn out daily, and 60 per cent left in. Thus, when

the stope is completed,

it is full of broken ore which can be drawn out at will.

The underhand method consists of drilling down into the ore, and

blasting it from sublevels

which have been driven across the stope at 50 foot

intervals, connecting

both manway raises. As the ore is broken, it falls by

gravity to the loading

chutes below, and can all be drawn out immediately.

The scraper method is used in places where the vein is not steep enough

for the ore to run

by gravity. At convenient locations, a small, double drum,

electrically driven

hoist is installed, equipped with Ys " steel cables, to which is

attached a steel scraper.

After the ore has been drilled and blasted, it is scraped

along the floor to

small ore pockets, from which it is loaded by gravity into the

tram cars.

lyon-a36.jpg = fullsize

Drillers Joseph Kwetcian, Arthur Stewart, and Supervisor Dan Evans

The drilling of the ore is done by high powered, compressed air drilling

machines of various

types and sizes, depending upon the character of work to be

performed. Due

to the extreme hardness and abrasiveness of the ore and rock,

the drill steel used

must be of the highest grade obtainable, and it is, therefore,

made from Chateaugay

iron.

Because of the hardness and density of the ore and rock, it is necessary

to

use high explosives

in all cases for blasting.

Drill sharpening shops are located on each level for sharpening the drill

steel, of which thousands

of pieces are used and dulled daily. The drillers,

including those on

development work, average 31 long tons drilled and blasted

per man per 8-hour

day.

The transportation of the ore from the working places to the main

hoisting shaft is accomplished

by electric, storage battery locomotives, and steel,

Granby type, side dump

cars, each having a capacity of six long tons, and

equipped with roller

bearings. The loading and tramming of each train is done

by two men, averaging

55 long tons per man per day for the entire mine.

After the ore is trammed to the main hoisting shaft, it is dumped into

the ore pass which

is connected to each level, and at the bottom of which is

located a large 48"

x 36" Jaw crusher for crushing the lumps of ore down to

8 inches and smaller.

The material from the crusher is discharged by gravity

into the skip loading

bins, where it is loaded into the 8-ton skips, hoisted

at the rate of 1,800

feet per minute, and dumped automatically into the bins

above the secondary

crushers in the headframe at the top of the shaft.

The mine is splendidly ventilated in a rather unique and inexpensive

way. The openings

from the old workings to the surface at the extreme

westerly end of the

mine are considerably higher than those on the easterly end.

During the long, cold

winter months, tremendous quantities of ice, hundreds of

thousands of tons,

accumulate in these workings, which cools the air sufficiently

to cause large volumes

to go down into the workings, forcing the smoke and

gases out through the

openings to the surface on the easterly end of the mine.

The ice, of course,

melts considerably during the summer months, but never

entirely, enough fortunately

remaining to insure ample ventilation of the mine

at all times.

The entire mine is so arranged that the water from all sections drains

by

gravity to points at,

or near, the main hoisting shaft, from which it is pumped

to the' surface by

electrically driven pumps. The quantity of water amounts to

about 500 gallons per

minute. It is very pure, contains no acids, and is

therefore not destructive

to the pumping equipment.

In many places in the mine, especially on the lower levels, a great deal

of timbering must be

done in order to support the back, or roof, of the main

drifts, on account

of the tendency of the ore and rock to spall and loosen.

The mine, as developed and equipped at the present time, is capable of

producing 2,000 long

tons of ore per 8-hour day, averaging 15 long tons per

man per 8-hour day

for all underground workmen.

MILLING AND CONCENTRATING

The purpose of milling and concentrating is to beneficiate the iron ore

by separating and eliminating

from it, insofar as is economically possible, all

of the rock and other

materials that might be associated with it when it comes

from the mine.

The Chateaugay ore, as mined, contains 28 per cent iron.

By milling and concentrating,

the iron content is brought up to 69 per cent.

Pure magnetite contains

72.4 per cent iron and 27.6 per cent oxygen.

When the ore comes from the mine, it is 8" and smaller in size.

The

fines, 2 1/2" and smaller,

are screened out by a rotary grizzly, and the larger pieces

crushed to 2 1/2" and

smaller, by two 10" x 72" jaw crushers in the headhouse,

at the top of the main

hoisting shaft. The ore is then conveyed, at the rate of

250 tons per hour,

by a 30" belt conveyor, to two 750 ton storage bins; from

the bottom of which

it is conveyed, at the rate of 250 tons per hour, by a 30"

belt conveyor to the

primary roll house, the first unit of the concentrating

plant.

The ore is now passed over vibrating screens with one inch square

openings. The

portion which passes over the screens goes to two 36" pulley

type, electro-magnetic

separators which are set and regulated to discard all

material containing

less than 6 per cent iron. This material is known as "coarse

tailings," and is sent

to the tailings pile. The iron bearing material retained

by the separators is

discharged, by gravity, to a set of 20" x 72", plain faced,

chrome steel rolls,

and is ground to 1 1/2" and smaller.

The material that passes through the screens, and which contains about

4 per cent moisture,

by weight, discharges by gravity into a 150 ton bin, from

which it is elevated

about 100 feet, vertically, by a belt and bucket type elevator,

and discharged into

the dryer. The dryer is a steel stack, about 125 feet high,

lined with fire brick,

and equipped with cast iron baffles, the purpose of which is

to retard the ore,

as it falls down through the stack. Hot gases, by which the

ore is dried, are produced

by a Coxe stoker, burning birdseye anthracite and

located near the bottom

of the dryer stack.

The material as it comes from the dryer, thoroughly dry, is conveyed by

a 24" steel conveyor

and discharged, along with the material from the rolls, onto

a 30" belt conveyor,

and sent direct to the secondary roll house, the second

unit of the concentrating

plant.

The material is now passed over double deck vibrating screens, having

10 mesh openings on

the bottom deck. The portion that passes over the screens

goes to four 36", pulley

type, electro-magnetic separators, which are set and

regulated to discard

all material containing less than 6 per cent iron. This

material is known as

medium size ore tailings, and is sent to the tailings pile.

The material retained

by the separators is discharged by gravity to three sets of

24" x 54", plain faced,

chrome steel rolls. The material, after leaving the

rolls, is returned,

in closed circuit, to the screens at the top of the building.

The material that passes through the screens is sent to a 30 foot, centri-

fugal air separator

for taking out all of the minus 100 mesh material, which is

sent direct to the

wet magnetic separators, in the concentrator house, the third

and last unit of the

concentrating plant. The coarse material from the air

separator, which is

minus 10 mesh, and plus 100 mesh, is conveyed, by a 30"

belt conveyor, direct

to the bins over the dry, magnetic separators, in the con-

centrator house.

The minus 10 mesh, dry material now passes over 16-30", drum type,

electro-magnetic separators,

making a concentrate containing 69 per cent iron

and better, and a tailing

containing not more than 3 per cent iron. The mid-

dlings from these separators

fall by gravity to 16 similar type separators

directly below, which

also make a concentrate containing 69 per cent iron and

better, and a tailing

containing not more than 3 per cent iron. The middlings

from these separators

are returned to the bins at the top of the building in closed

circuit. The

concentrates are sent to two 500-ton storage bins, at the top of

the sintering plant

and the tailings are sent to the tailings pile.

Because the minus 100 mesh material cannot be efficiently separated on

dry drum type magnetic

separators, it is sent to 8 belt type wet magnetic separa-

tors where, as it passes

over the magnetic field, the tailings or gangue is thor-

oughly washed out by

a spray of water. These separators make a 70 per cent

iron concentrate, and

a tailing containing not more than 2 per cent iron. The

concentrates are sent

to the storage bins above the sintering plant.

The ore tailings, or rock that has been separated from the ore, has

become a very valuable

by-product during the last ten years. Each commercial

size is stored separately

in piles above a concrete tunnel, through which a 36"

belt conveyor takes

it to railroad cars for shipment to market.

The concentrating plant has a capacity for treating, efficiently, 2,000

long tons of ore in

8 hours as it 'comes from the mine, from which 800 long tons

of concentrates, containing

69 per cent iron, are produced.

SINTERING

The purpose of sintering is to improve the physical character of the

concentrated ore by

fusing the ore particles into a cellular mass, which makes it

much more desirable

for use in the blast furnaces, where most of it goes.

Sintering is accomplished, at this plant, by means of a Dwight & Lloyd,

continuous machine,

6 ft wide and 69 ft. long, comprised of a series of perfor-

ated grates, known

as pallets, which are mounted on wheels for traveling on a

continuous track.

The concentrated ore is first mixed with about 5 1/2 per cent by weight

of anthracite.

The fuel is about the size of granulated sugar, very high

in carbon, and low

in ash, and is known as Anthrafine. It is produced by the

Hudson Coal Company,

and is most desirable as a fuel for sintering purposes.

As the fuel and the concentrated ore are being mixed, by means of a pug

mill, a small amount

of water is added as a temporary binder. This mixture of

ore and fuel is spread

evenly on the pallets of the sintering machine, to a thick-

ness of about 6 inches,

and the fuel is immediately ignited as it passes under an

oil heated ignition

furnace, comprised of high temperature, refractory brick,

and a retort, or combustion

chamber, suspended by a steel and cast iron frame.

Combustion is assisted by a downward current of air, drawn through

the mixture, or bed,

the entire length of the machine, by a large induced draft

fan.

The speed at which the machine travels is regulated so that, by the time

the material reaches

the discharge end, the fuel is entirely burned out and the

process completed.

The sinter is then discharged over a set of stationary grizzly

bars, spaced one inch

apart, which take out the fines, allowing only the coarse

material to go to the

railroad car for shipment. The fines are returned, by

means of an inclined

belt conveyor, and are mixed with the incoming feed to

the sintering machine.

The plant has an output capacity of 50 long tons of sintered ore per

hour, and can be opearted,

continuously and efficiently, 16 hours daily, (two

8-hour shifts) or 24

hours daily, (three 8-hour shifts,) by suspending opera-

tions one day each

week for maintenance and repairs.

Go to Mine History Page 5 ........

![]()